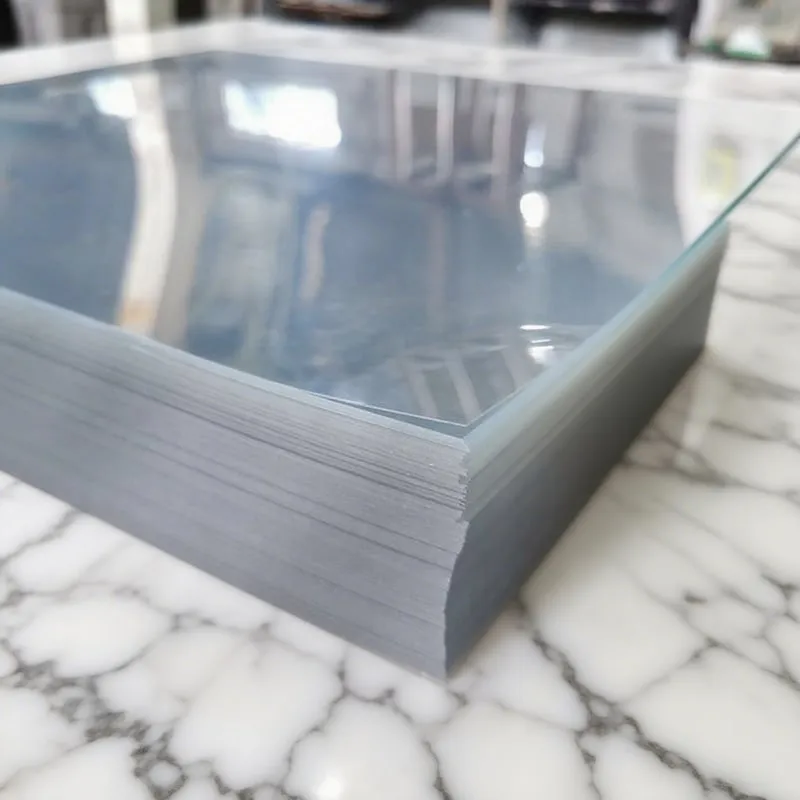

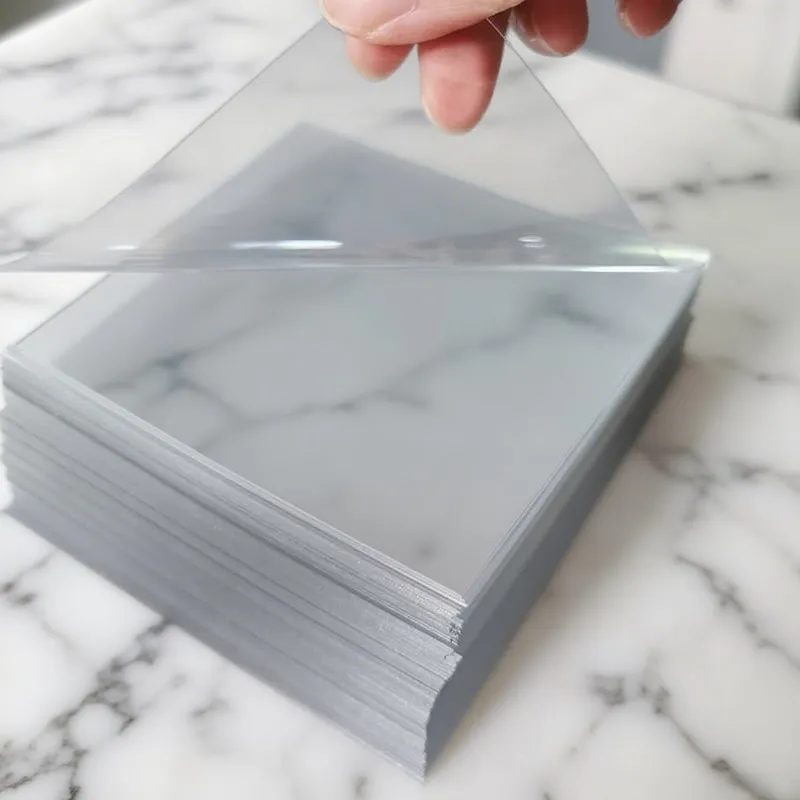

Versatile Plastic Sheets for Every Industry Need

Discover our high-quality plastic sheets available in a variety of materials, including PET, PVC, PP, and more. With customizable specifications and thicknesses, our sheets are ideal for a wide range of applications, from packaging to industrial manufacturing.

Plastic Sheet Roll Storage for Manufacturing and Packaging Materials

Our warehouse features a wide variety of plastic sheet rolls, including high-quality PET, PVC, PP, and more, in various specifications and thicknesses. These raw materials are stored and organized for efficient distribution to meet the needs of packaging, industrial manufacturing, and thermoforming applications. With a robust inventory management system, we ensure prompt delivery and customized solutions tailored to your requirements.

Eco-Friendly PET Sheets and Rolls for Various Applications

Explore our diverse range of eco-friendly PET sheets and rolls, including Anti-fog PET Sheet, Normal PET Sheet, APET/PETG Sheet, and Anti-fog PET Roll. Designed for a variety of applications such as packaging, manufacturing, and display, our PET materials offer superior clarity, durability, and environmental benefits. Click to view more details on each product category and discover the perfect solution for your needs.

The Common Pitfalls When Purchasing Plastic Sheets

Purchasing Plastic Sheet can be a complex process with several potential pitfalls. Here are a few common ones to be mindful of:

Issue: Choosing generic, low-cost films without considering specific use cases (e.g., food packaging requires FDA-grade certification; outdoor use demands UV resistance).

Solution: Define requirements upfront (temperature tolerance, chemical resistance, light transmission) and prioritize material properties (e.g., PP for heat sealing, PET for high clarity).

Issue: Overlooking cutting precision, Minimum Order Quantity (MOQ), or roll slitting methods, causing production issues.

Solution: Confirm customization parameters in writing (e.g., roll length, edge smoothness).

Issue: Plastic sheets degrading, warping, or yellowing in extreme temperatures/humidity (e.g., PVC softens at high heat; PET becomes brittle in cold).

Solution: Request material weathering data (e.g., ASTM test results) from suppliers.

Issue: Films arriving damaged due to moisture, scratches, or compression during shipping.

Solution: Ensure suppliers use moisture-proof packaging + wooden crates and provide proper storage guidelines (store flat, avoid sunlight).

Issue: Cheap films prone to tearing, increasing replacement frequency and labor costs.

Solution: Calculate Total Cost of Ownership (TCO) and prioritize cost-performance balance.

Issue: Bulk films arriving incompatible with equipment (e.g., mismatched heat-sealing temperatures).

Solution: Always request free samples and simulate real-world application tests.

The FAQs About Plastic Sheets

These are the most frequently asked questions. If you cannot find an answer here, please contact us via email

What are the different types of plastic sheets and their uses?

Plastic sheets come in a variety of types, each with unique material properties and applications. Below are the three most commonly used types of plastic sheets:

1. PET Plastic Sheet (Polyethylene Terephthalate)

- Features:

- High transparency

- Scratch resistance

- Chemical corrosion resistance

- Environmentally friendly and recyclable

- Common Applications:

- Food packaging boxes

- Electronic component protection covers

- Medical device trays

- Advantages:

- Meets food-grade safety standards (e.g., FDA certification)

- Lightweight and easy to process

2. PVC Plastic Sheet (Polyvinyl Chloride)

- Features:

- Acid and alkali resistance

- Flame retardant (in some models)

- Good insulation properties

- Low cost

- Common Applications:

- Chemical storage tank linings

- Advertising display boards

- Building partitions

- Advantages:

- Customizable color and hardness (e.g., soft PVC for shock pads)

3. PP Plastic Sheet (Polypropylene)

- Features:

- High temperature resistance (up to 100°C)

- Good flexibility

- Strong fatigue resistance

- Common Applications:

- Water tank linings

- Laboratory countertops

- Logistics turnover boxes

- Advantages:

- Weldable and easy to clean

- Suitable for long-term repeated use

How do I choose the right plastic sheet for my project?

Choosing the right plastic sheet depends on several factors, including the specific properties required for your project. Here’s a breakdown of the key considerations for selecting between PET, PVC, and PP:

1. Material Properties

PET (Polyethylene Terephthalate):

- Transparency: PET is known for its high clarity, making it ideal for applications that require transparency, such as food packaging and protective covers.

- Durability: It is highly scratch-resistant and resistant to chemical corrosion.

- Environmental Impact: PET is recyclable and environmentally friendly, making it a good choice for sustainability-conscious projects.

PVC (Polyvinyl Chloride):

- Chemical Resistance: PVC is highly resistant to acids, alkalis, and other chemicals, making it suitable for use in harsh environments like chemical storage or industrial applications.

- Versatility: Available in both flexible and rigid forms, PVC can be customized for a wide range of applications, including signage, partitions, and electrical insulation.

- Cost-Effective: PVC is generally more affordable, making it a great option for budget-conscious projects.

PP (Polypropylene):

- Temperature Resistance: PP can withstand high temperatures up to 100°C, making it suitable for applications involving heat or elevated temperatures.

- Flexibility: PP offers excellent flexibility and fatigue resistance, making it ideal for applications that require repeated bending or movement.

- Weldability: PP can be easily welded, making it a good choice for projects that require joining multiple pieces.

2. Functional Considerations

- Impact Resistance:

- PVC and PP both offer good impact resistance, but PP is especially durable for applications requiring long-term, repeated use, such as storage containers or laboratory countertops.

- UV Resistance:

- PET offers excellent UV resistance, making it perfect for outdoor applications such as signage or displays exposed to sunlight.

- Flame Retardance:

- PVC can be flame-retardant in certain grades, making it ideal for applications requiring fire resistance, such as electrical insulation or construction materials.

3. Application-Specific Needs

- PET is ideal for projects that require high transparency and a sleek, polished appearance, such as food packaging, electronic covers, and medical trays.

- PVC is perfect for industrial, chemical, and construction applications, including tank linings, partitions, and display boards. It is also highly customizable in color and hardness.

- PP is best for applications requiring heat resistance, flexibility, and fatigue resistance, such as laboratory countertops, water tank linings, and logistics boxes.

4. Cost and Budget

- PVC is generally the most cost-effective option, making it a great choice for projects that prioritize affordability without compromising on quality.

- PET and PP may be more expensive, but they offer enhanced properties such as greater transparency (PET) and better temperature resistance (PP), making them suitable for more specialized or demanding applications.

Can plastic sheets be cut to custom sizes?

Yes! We specialize in precisely customized plastic sheets to match your project’s unique requirements. Here’s how we ensure a seamless experience:

Key Details:

Materials Supported: PET, PVC, PP, and more - no material limitations.

Customization Options:

Dimensions: Exact length, width, and thickness.

Shapes: Standard or complex geometries (e.g., circles, panels with cutouts).

Formats: Choose between individual sheets or full rolls.

How to Order:

For Sheet Orders:

Provide:

Material type (e.g., PET/PVC/PP).

Thickness (mm or inch).

Dimensions (L × W × H).

For Roll Orders:

Specify:

Material type.

Thickness.

Roll length (meters/feet).

Why Choose Us?

Precision Cutting: Laser/CNC cutting with ±0.5mm accuracy.

No Minimum Order: Flexible for prototypes or bulk needs.

Free Consultation: Need guidance? Our engineers will optimize your design.

Example Request:

“I need 10 PVC sheets (5mm thick) cut to 120cm × 60cm for xxx.”

How should I clean and maintain plastic sheets?

Proper care ensures longevity for your plastic sheets. Below are material-specific guidelines for PET, PVC, and PP:

Cleaning Instructions

PET (Polyethylene Terephthalate)

Do:

Wipe with a soft microfiber cloth dampened with mild soapy water (e.g., dish soap diluted in warm water).

For stubborn stains, use isopropyl alcohol (70% or less) sparingly.

Avoid:

Acetone, ammonia-based cleaners, or abrasive pads (risk of clouding or scratching).

PVC (Polyvinyl Chloride)

Do:

Clean with a neutral pH detergent (e.g., hand soap) and lukewarm water.

Rinse thoroughly to prevent residue buildup.

Avoid:

Bleach, solvents, or scouring sponges (may degrade the surface).

PP (Polypropylene)

Do:

Use a mixture of water and white vinegar (1:1 ratio) for grease or dirt.

Dry immediately with a lint-free cloth.

Avoid:

High-temperature steam cleaning (may warp the sheet).

Maintenance Tips

Storage:

Keep sheets flat or vertically supported to prevent warping.

Store in a cool, dry place away from direct sunlight (UV exposure can discolor PET and PP over time).

Temperature:

Avoid prolonged exposure to temperatures above:

PET: 70°C (158°F)

PVC: 60°C (140°F)

PP: 100°C (212°F)

Quick Reference Table

| Material | Safe Cleaners | Avoid | Max Temp |

|---|---|---|---|

| PET | Mild soap, isopropyl alcohol | Acetone, ammonia | 70°C |

| PVC | Neutral detergent | Bleach, solvents | 60°C |

| PP | Water + vinegar | Steam cleaners | 100°C |

What is the temperature range and impact resistance of plastic sheets?

Plastic sheets vary significantly in thermal and mechanical performance depending on the material. Below are key specifications for PET, PVC, and PP:

1. PET (Polyethylene Terephthalate)

Temperature Range:

Continuous Use: -40°C to 70°C (-40°F to 158°F)

Short-Term Peak: Up to 100°C (212°F) for limited exposure.

Impact Resistance:

Moderate resistance; suitable for lightweight applications.

Prone to cracking under sudden heavy force.

Best For: Food packaging, electronics enclosures, and displays requiring clarity.

2. PVC (Polyvinyl Chloride)

Temperature Range:

Continuous Use: -20°C to 60°C (-4°F to 140°F)

Avoid Prolonged Heat: Warps above 70°C (158°F).

Impact Resistance:

Low to moderate; rigid PVC is brittle in cold temperatures.

Flexible PVC grades offer better shock absorption.

Best For: Indoor signage, chemical tanks, and electrical insulation.

3. PP (Polypropylene)

Temperature Range:

Continuous Use: 0°C to 100°C (32°F to 212°F)

Short-Term Peak: Up to 120°C (248°F).

Impact Resistance:

High resistance—excellent for rugged environments.

Retains flexibility even at low temperatures.

Best For: Automotive parts, laboratory equipment, and hot liquid containers.

Quick Comparison Table

| Material | Temp Range (°C) | Impact Resistance | Key Limitation |

|---|---|---|---|

| PET | -40°C to 70°C | Moderate | Avoid heavy impacts |

| PVC | -20°C to 60°C | Low-Moderate | Brittle in cold |

| PP | 0°C to 100°C | High | Softens near upper temp limit |

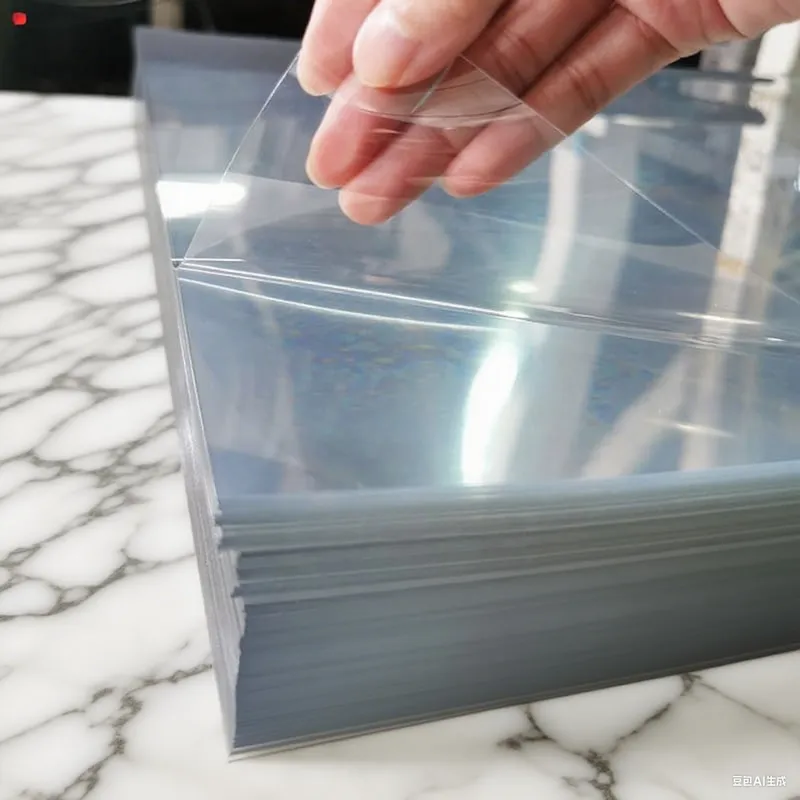

How can I prevent plastic sheets from being scratched or deformed during transportation?

We ensure safe shipping by using anti-scratch film packaging, reinforced with wooden frames and protective corners. These measures help prevent damage during transport.

Do you offer discounts for wholesale orders?

Yes, we provide tiered pricing for bulk orders with a minimum order quantity (MOQ) of 100 pieces. Exclusive customer service is available for large wholesale orders. Contact us for more information and to get a custom quote.

Various Customized Professional Services

We will provide the best solution for your projects. Customer satisfaction is always our pursuit.