A Compliance Guide for Modern Brands

Blister packaging is a staple across industries—from pharmaceuticals to consumer goods—but its widespread use comes with a complex web of regulations. Non-compliance can lead to costly recalls, legal penalties, or reputational damage. Whether you’re a startup or an established brand, understanding these rules is critical. Let’s break down the key regulations governing blister packaging and how to navigate them.

1. Material Safety: Avoiding Toxic Risks

Blister packs must comply with strict safety standards to prevent chemical leaching or contamination. Key regulations include:

- FDA (U.S.): Materials like PVC, PET, or foil must meet FDA 21 CFR requirements for indirect food contact or pharmaceutical use. Certain plasticizers (e.g., DEHP) are restricted.

- EU REACH: Bans phthalates and heavy metals (e.g., lead, cadmium) in packaging materials.

- Proposition 65 (California): Requires warnings if packaging contains chemicals linked to cancer or reproductive harm.

Blistera’s Fix:

✔ We use FDA-approved, phthalate-free polymers and provide full material transparency reports for compliance audits.

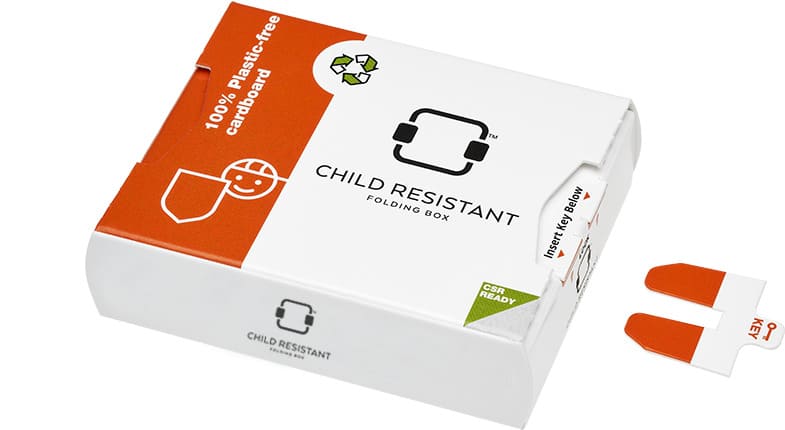

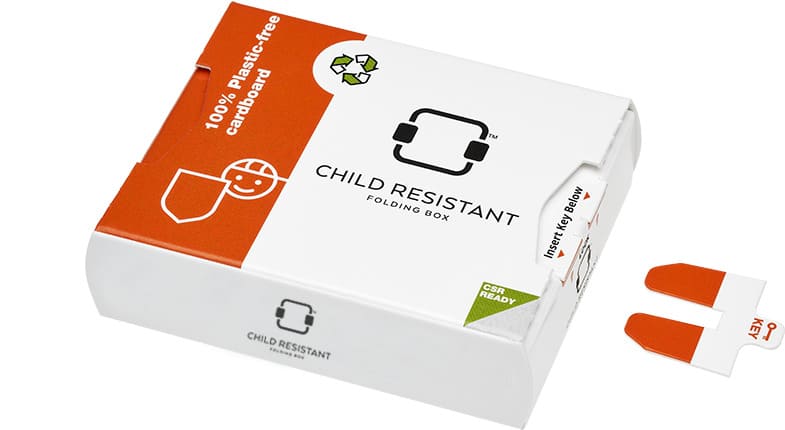

2. Child-Resistant (CR) Packaging: Protecting Vulnerable Users

For pharmaceuticals, cannabis, or hazardous products, child-resistant features are often legally mandated:

- Poison Prevention Packaging Act (PPPA, U.S.): Requires CR packaging for medications, nicotine, and household chemicals.

- ISO 8317 (Global): Certifies child-resistant closures that adults can open within 5 minutes.

- EU Child Safety Standards: EN 14375 for pharmaceuticals and EN 862 for non-pharmaceuticals.

Blistera’s Fix:

✔ Our CR designs combine intuitive adult access (e.g., peel-and-push tabs) with rigorous ISO testing.

3. Sustainability Mandates: Reducing Plastic Waste

Governments are cracking down on single-use plastics and non-recyclable packaging:

- EU Packaging and Packaging Waste Directive (PPWD): Requires 70% recyclability for packaging by 2030; PVC blisters face phase-outs.

- Extended Producer Responsibility (EPR) Laws: Brands in Canada, France, and the UK must fund blister pack recycling.

- California SB 54: Mandates 100% recyclable or compostable packaging by 2032.

Blistera’s Fix:

✔ Our plant-based, mono-material blisters meet recyclability targets and avoid restricted plastics like PVC.

4. Pharmaceutical Labeling & Tamper Evidence

Drugs and supplements require blister packs to:

- Display expiry dates, batch numbers, and dosing instructions per FDA 21 CFR §211.

- Include anti-counterfeiting measures (e.g., serialized barcodes under the EU Falsified Medicines Directive).

- Ensure tamper-evident seals (per USP <671> for U.S. markets).

Blistera’s Fix:

✔ We integrate QR codes, NFC tags, and tamper-proof foil seals that comply with global pharmaceutical standards.

5. Accessibility Requirements

Packaging must be usable for all populations:

- ADA (U.S.): Braille labeling for prescription drugs (EU Annex VI mandates Braille on meds).

- Senior-Friendly Design: Easy-open features without compromising child resistance.

Blistera’s Fix:

✔ Our blisters combine embossed Braille, clear typography, and peelable layers for universal access.

How to Stay Ahead of Blister Packaging Regulations

✔ Audit Your Materials: Replace PVC with PET or bio-based alternatives.

✔ Test Early: Validate child resistance, aging, and stability (e.g., 6-month shelf-life simulations).

✔ Partner with Experts: Work with suppliers who pre-certify designs for your target markets.

Simplify Compliance with Blistera

Navigating blister packaging regulations doesn’t have to mean sacrificing innovation. At Blistera, we engineer compliant, future-proof solutions that align with global standards – from FDA to EU Green Deal requirements.

Need a Compliance Check?

📞 Book a Free Consultation to ensure your packaging meets today’s rules and tomorrow’s trends!